Antenna Development and Manufacturing Center Berlin/Brandenburg

In-House Production

In the wireless communications technology market, the name ANTONICS stands for innovative planar antenna system technology and the development of new areas of applications and innovations. ANTONICS is regarded as an innovation leader in the field of planar railway antenna technology and is a pioneer in the market.

The focus lies on customer-specific products which are developed and produced based on clients’ needs.

As part of the site investments in Velten, ANTONICS has purchased state-of-the-art robotics, turning, milling, antenna simulation, and antenna special technology, thus creating the basis for Germany's most modern antenna development and production center. The focus of production is based on rail transport technology and the railway industry, one of the most important sectors and industries in the Berlin / Brandenburg region. Manufacturing of all mechanical precision parts takes place in-house.

Technology

Antonics is considered a pioneer in commercial planar antenna technology and has become a leading supplier of railway and vehicle antennas.

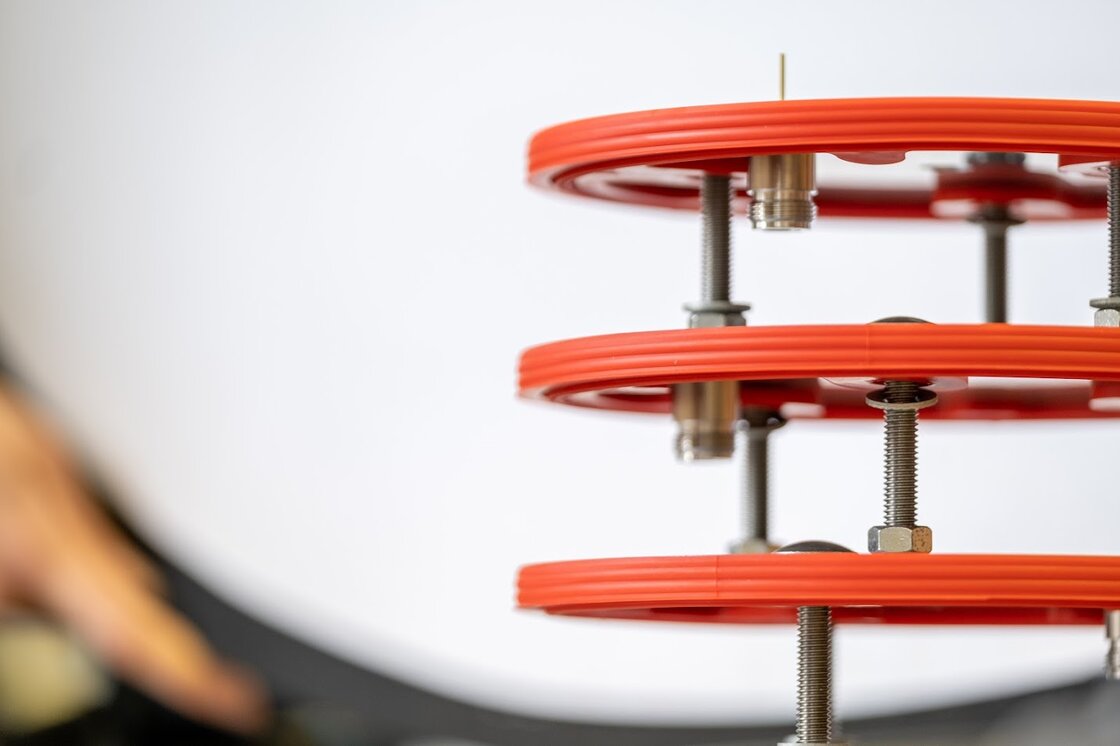

The advantages of planar antenna technology lie in the significantly higher performance, the extreme miniaturization, the multifunctionality, the integrability into systems, and thus the creation of prerequisites for application in complex areas of application. With these products, it is possible - compared to other products in the market - to react much more flexibly to market requirements.

With the new ANTONICS antenna structures, extremely flat antenna designs are achieved, and above-average bandwidths are attained in relation to a very low counterweight. Very high antenna efficiency is realized exclusively by metallic antenna excitation structures. Due to the selective coupling of the respective frequency range via high-quality N and TNC series connectors, no cost-intensive splitters are required compared to already-known broadband antennas. This selective coupling significantly improves the efficiency of the single bands compared to conventional multiband broadband concepts with only one connection.

ANTONICS offers its clients full technological support in the concrete everyday project life and solves specific problems. We look forward to supporting our clients regarding questions of compliance with the prescribed structure gauge or on highly complex RF simulations of the antenna radiation characteristics on the vehicle roof with surrounding vehicle bodies.

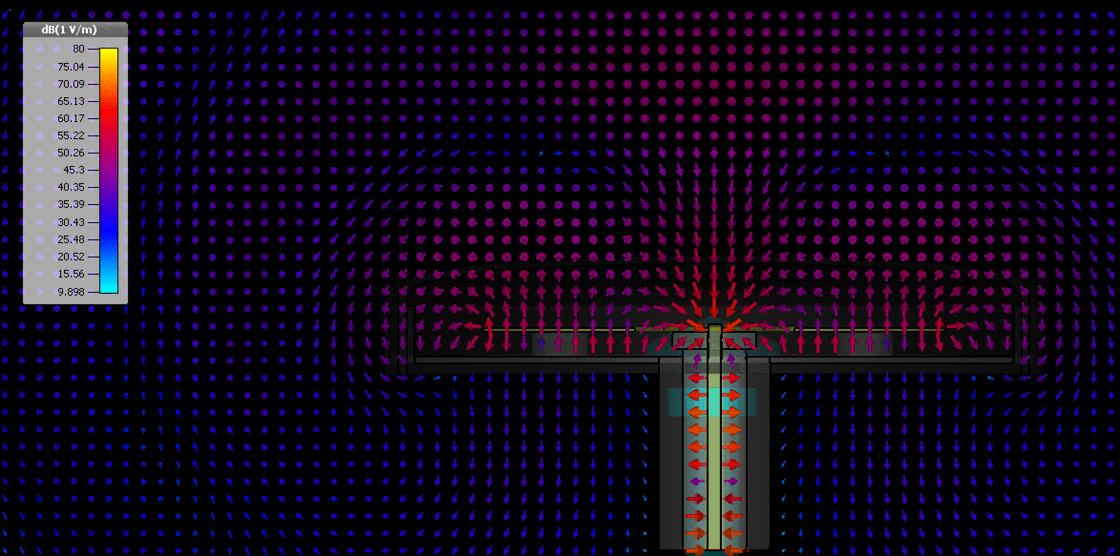

RF-Techology

ANTONICS is regarded as an innovation leader in the planar railway antenna technology field and drives the railway industry forward in this area. The advantages of planar antenna technology lie in the significantly higher performance, the extreme miniaturization, the multifunctionality, the integrability into systems, and thus the creation of prerequisites for application in complex areas of application.

Due to the selective coupling of the respective frequency range via high-quality N and TNC series connectors, no cost-intensive splitters are required, as with already-known broadband antennas. This selective coupling significantly improves the efficiency of the single bands compared to conventional multiband broadband concepts with only one connection.

ANTONICS offers its clients full technological support in the concrete everyday project life and solves specific problems. ANTONICS supports its clients on all kinds of questions of compliance with the prescribed structure gauge or on highly complex RF simulation of the antenna radiation characteristics on the vehicle roof, with surrounding vehicle bodies for example.

Precision Mechanical Development & Design

Antonics works with modern 3D CAD (Computer Aided Design) and RF simulation tools. Corresponding 3D data is made available internally to production as well as externally to the customer, e.g., as a step file. With the innovative Antonics antenna structures, extremely flat antenna designs are achieved, and above-average bandwidths are realized in relation to a very low counterweight. Very high antenna efficiency is found by exclusively metallic antenna excitation structures.

The vertical range of manufacture is approx. 85%, i.e. all metallic milled and turned parts are manufactured in-house on state-of-the-art robotics, turning and milling machines. The assembly, final assembly and 100% testing take place in the antenna development and production center Berlin / Brandenburg. As a result, we can guarantee consistent delivery dates for small series and large-scale projects and are not dependent on the production capacities of corresponding suppliers.